In today’s fast-paced industrial landscape, businesses face mounting pressure to optimize efficiency, reduce costs, and ensure workplace safety. While traditional tools like forklifts and manual carts have long been staples in warehouses and factories, the rise of automation has introduced a game-changing alternative: CPJROBOT Smart Following Robots. This article compares these two approaches across critical dimensions—automation, flexibility, ease of use, and environmental adaptability—to reveal why intelligent robots are redefining the future of material handling.

Traditional Material Handling Tools: Pros and Cons

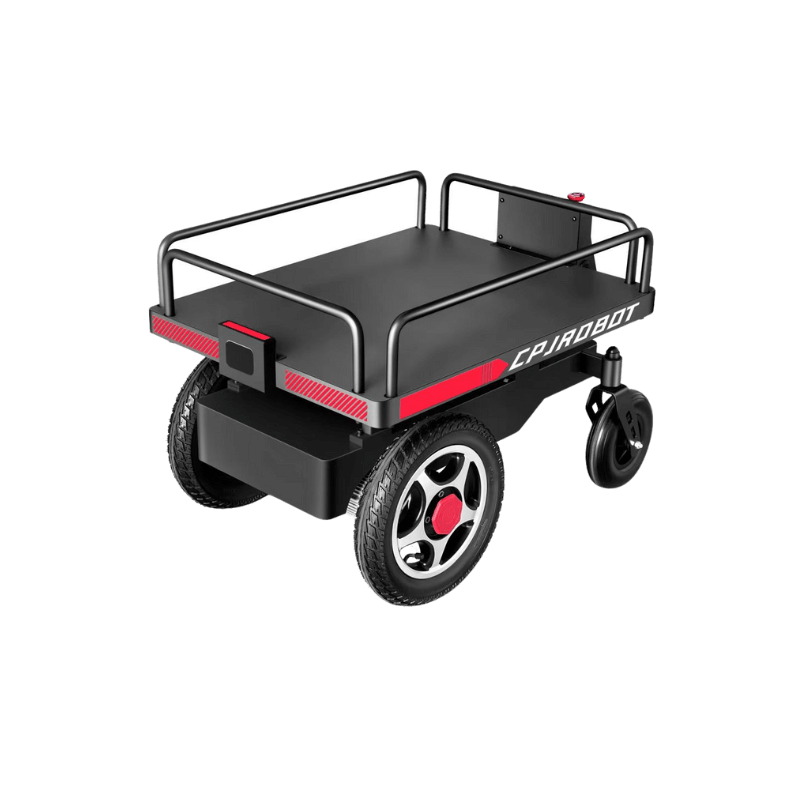

Manual Carts

Pros:

- Low Cost: Simple design with minimal upfront investment.

- Ease of Use: No specialized training required for operation.

Cons:

- Low Efficiency: Reliant on human labor, leading to fatigue and slower workflows.

- Limited Capacity: Suitable only for lightweight items (typically under 500 kg).

- Environmental Constraints: Struggles on uneven terrain or in low-light conditions.

Forklifts

Pros:

- Heavy-Duty Handling: Capable of moving large, bulky items.

Cons:

- High Operational Costs: Fuel, maintenance, and operator training expenses add up.

- Safety Risks: Human error contributes to frequent accidents.

Common Limitations of Traditional Tools:

- Low Automation: Reliant on manual operation, hindering scalability.

- Inflexibility: Struggles to adapt to dynamic workflows (e.g., mixed-product sorting).

- Safety Gaps: Accidents caused by fatigue or misjudgment remain prevalent.

CPJROBOT Smart Following Robots: The Next-Gen Solution

Combining LiDAR sensors, AI algorithms, and real-time data processing, CPJROBOT Smart Following Robots deliver unparalleled advantages for modern factories:

1. Automation Revolution

- Precision Navigation: Achieves centimeter-level positioning accuracy via SLAM (Simultaneous Localization and Mapping) technology.

- Auto-Follow Mode: Tracks operators in real time, dynamically optimizing paths to avoid obstacles.

- Efficiency Gains: In one e-commerce case study, deploying 50 robots reduced order processing time from 48 hours to 6 hours while cutting labor costs by 60%.

2. Enhanced Flexibility

- Compact Design: With dimensions of 1.2m × 0.8m × 1.1m (60% smaller than traditional carts) and a turning radius of ≤0.5m, it maneuvers effortlessly in narrow aisles.

- Multi-Scenario Adaptability: Operates in temperatures from -20°C to 50°C and features IP65-rated protection for dustproof/waterproof performance.

3. Superior Environmental Adaptability

- Rugged Terrain Handling: Four-wheel independent drive enables navigation on slopes up to 15° and uneven surfaces.

- Heavy Payload Capacity: Transports up to 1.5 tons, outperforming most manual carts.

4. Proactive Safety Systems

- Collision Avoidance: Responds to obstacles within ≤0.2 seconds, with emergency braking distance under 0.3 meters.

- 360° Monitoring: Laser sensors create a real-time safety buffer zone around the robot.

Proven Industry Applications

1. E-Commerce Warehousing

A leading platform deployed 100 CPJROBOT robots to build a “goods-to-person” picking network, achieving:

- 40% increase in storage space utilization.

- 99.99% order accuracy (up from 92%).

- 8-hour returns processing (down from 72 hours).

2. Automotive Manufacturing

A global automaker integrated robots for engine component delivery, resulting in:

- 100% on-time delivery to production lines.

- 300 fewer hours of annual downtime.

3. Agricultural Cold Chain

In greenhouse logistics, CPJROBOT robots reduced:

- Product loss from 8% to 2%.

- Operating costs by 25% in humid, dusty environments.

Conclusion: The Future Belongs to Smart Automation

Traditional tools, while familiar, are increasingly incompatible with the demands of modern factories. CPJROBOT Smart Following Robots address these gaps head-on by delivering:

- Efficiency: Freeing workers to focus on high-value tasks like inventory management.

- Cost Savings: Slashing long-term operational and accident-related expenses.

- Safety: Transitioning from reactive to proactive risk prevention.

For businesses aiming to stay competitive, adopting CPJROBOT isn’t just an upgrade—it’s a strategic imperative. Embrace the future of smart logistics today and transform your factory floor into a hub of innovation and productivity.

Ready to revolutionize your workflow? [Contact us] to explore CPJROBOT Smart Following Robots and unlock next-level efficiency!