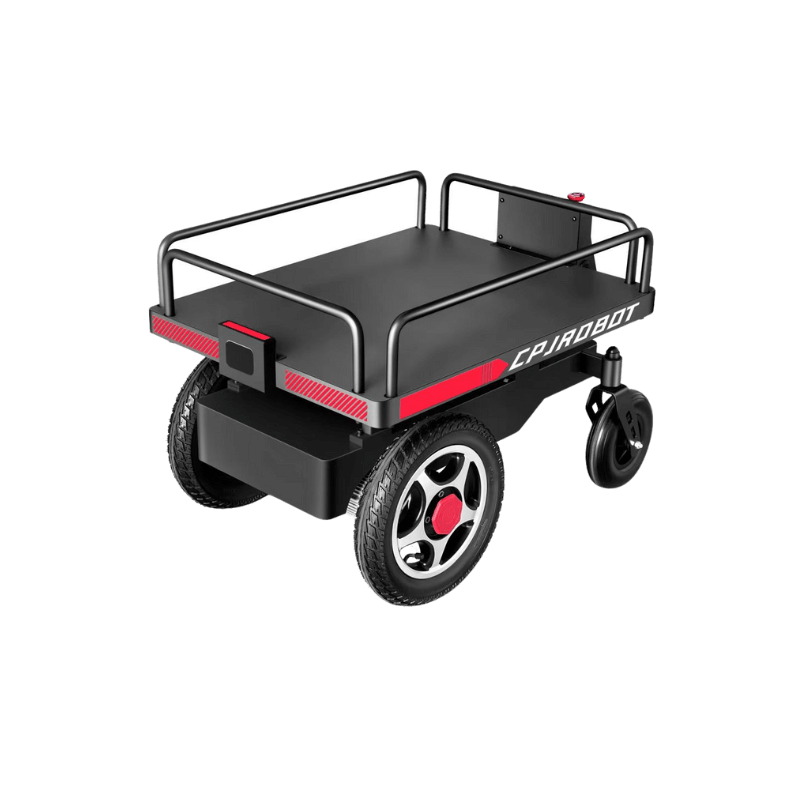

In the era of Industry 4.0, industrial automation is no longer a luxury but a necessity. Among the many innovations driving this transformation, TrackBot, an intelligent material handling robot, stands out as a game-changer. Designed to optimize workflows in factories, logistics, and warehousing, TrackBot is redefining how industries approach material handling. With features like auto-follow, wireless remote control, and autonomous obstacle avoidance, TrackBot is not just a robot—it’s a smart companion that enhances efficiency, reduces labor costs, and improves safety.

In this blog, we’ll explore how TrackBot is revolutionizing industrial material handling and why it’s a must-have for businesses aiming to stay competitive in the age of automation.

What is TrackBot?

TrackBot is an intelligent material handling robot equipped with cutting-edge technologies to streamline industrial workflows. Its key features include:

- Auto-Follow Technology: TrackBot can follow operators within a range of 1 to 7 meters, ensuring seamless movement without constant manual intervention.

- Wireless Remote Control: Users can easily guide the robot using a handheld remote, making it ideal for navigating complex environments.

- Autonomous Obstacle Avoidance: With multiple sensors, TrackBot detects and avoids obstacles in real-time, ensuring safe and efficient operations.

- High Load Capacity: Capable of carrying up to 100 kilograms, TrackBot is perfect for heavy-duty tasks in industrial settings.

- Multi-Mode Switching: The robot can switch between follow-mode, remote-control mode, and manual mode, offering flexibility for diverse tasks.

These features make TrackBot a versatile and reliable solution for industries looking to enhance their material handling processes.

How TrackBot Optimizes Industrial Material Handling

1. Streamlining Factory Operations

In manufacturing plants, material handling is a critical yet time-consuming task. TrackBot automates this process by following workers and transporting tools, components, or finished products across the factory floor. This reduces downtime and allows workers to focus on higher-value tasks, significantly boosting productivity.

For example, in automotive assembly lines, TrackBot can deliver parts to different stations, ensuring a smooth and uninterrupted workflow. Its autonomous obstacle avoidance feature ensures it navigates safely around machinery and workers, minimizing the risk of accidents.

2. Revolutionizing Logistics and Warehousing

Logistics and warehousing operations often involve repetitive tasks like sorting, stacking, and transporting goods. TrackBot excels in these environments by automating material movement, reducing reliance on manual labor, and speeding up operations.

In large warehouses, TrackBot can follow workers to transport goods from storage areas to loading docks, eliminating the need for manual carts or forklifts. Its high load capacity ensures it can handle heavy pallets with ease, while its wireless remote control allows for precise navigation in tight spaces.

3. Enhancing Safety in Industrial Environments

Safety is a top priority in industrial settings, and TrackBot is designed with this in mind. Its autonomous obstacle avoidance system uses advanced sensors to detect and avoid obstacles, preventing collisions and ensuring safe operation. Additionally, the robot’s auto-stop feature activates if it exceeds the set safety distance, further enhancing safety.

By reducing the need for manual material handling, TrackBot also minimizes the risk of workplace injuries, creating a safer environment for workers.

4. Reducing Labor Costs

Labor costs are a significant expense in industrial operations. TrackBot helps businesses reduce these costs by automating repetitive and labor-intensive tasks. With TrackBot handling material movement, companies can reallocate human resources to more strategic roles, improving overall operational efficiency.

For instance, in large-scale supermarkets or distribution centers, TrackBot can transport goods across long distances, reducing the need for multiple workers and cutting down on labor expenses.

5. Adapting to Diverse Environments

One of TrackBot’s standout features is its ability to operate seamlessly in both indoor and outdoor environments. Whether it’s a factory floor, a warehouse, or an agricultural greenhouse, TrackBot can navigate complex terrains and adapt to various scenarios. This versatility makes it an ideal solution for industries with diverse material handling needs.

Real-World Applications of TrackBot

– Factory Workshops

TrackBot is widely used in manufacturing plants to transport raw materials, tools, and finished products. Its auto-follow feature ensures it keeps up with workers, while its high load capacity makes it suitable for heavy-duty tasks.

– Warehouses and Distribution Centers

In logistics, TrackBot automates the movement of goods, reducing the time and effort required for sorting and distribution. Its wireless remote control allows for precise navigation in crowded spaces, ensuring efficient operations.

– Agricultural Greenhouses

TrackBot is also making waves in agriculture, where it transports produce within greenhouses. Its ability to navigate uneven terrain and avoid obstacles makes it a valuable asset in this sector.

– Large-Scale Supermarkets

In retail, TrackBot can transport goods across large supermarket floors, ensuring timely restocking and efficient operations.

Why Choose TrackBot for Industrial Automation?

- Increased Efficiency: TrackBot automates repetitive tasks, allowing workers to focus on more strategic activities.

- Cost Savings: By reducing labor costs and minimizing errors, TrackBot helps businesses save money.

- Enhanced Safety: With its autonomous obstacle avoidance and auto-stop features, TrackBot ensures a safer work environment.

- Versatility: TrackBot’s ability to operate in diverse environments makes it suitable for a wide range of industries.

Conclusion

TrackBot is more than just a material handling robot—it’s a smart solution for industries looking to enhance their automation capabilities. By optimizing workflows, reducing labor costs, and improving safety, TrackBot is helping businesses achieve new levels of efficiency and productivity.

Whether you’re running a factory, managing a warehouse, or operating a large-scale supermarket, TrackBot is the intelligent material handling robot you need to stay ahead in the competitive world of industrial automation. Embrace the future of material handling with TrackBot and experience the transformative power of intelligent automation.

Keywords: TrackBot, intelligent material handling robot, industrial automation, factory efficiency, logistics optimization, warehouse automation, safety in industrial environments, labor cost reduction.