Introduction

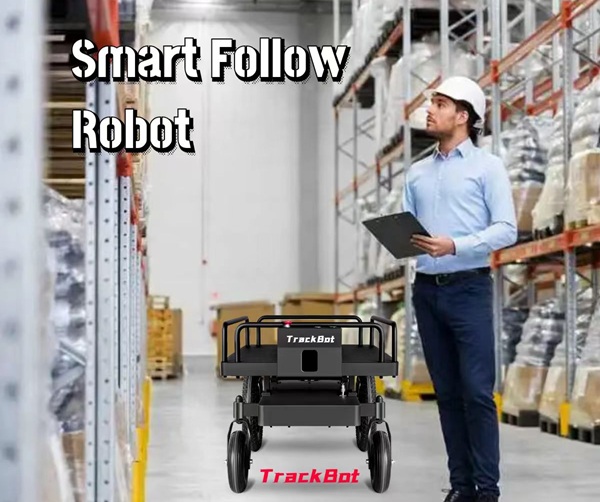

In the rapidly evolving world of manufacturing and logistics, Lightweight Automated Guided Vehicles (AGVs) are paving the way for more efficient material handling. These compact, mobile robots are designed to move materials through facilities with minimal human intervention, improving operational efficiency while reducing labor costs. With their ability to navigate tight spaces and adapt to dynamic workflows, lightweight AGVs are becoming indispensable in industries ranging from automotive manufacturing to e-commerce fulfillment centers.

CPJ ROBOT, a leader in reception service robot manufacturing, offers fully customizable lightweight AGV solutions, ensuring businesses can enhance their operations with tailored automation systems.

1. Key Features of Lightweight AGVs

Lightweight AGVs are engineered for maximum versatility and flexibility in industrial settings. Here are some of their key features:

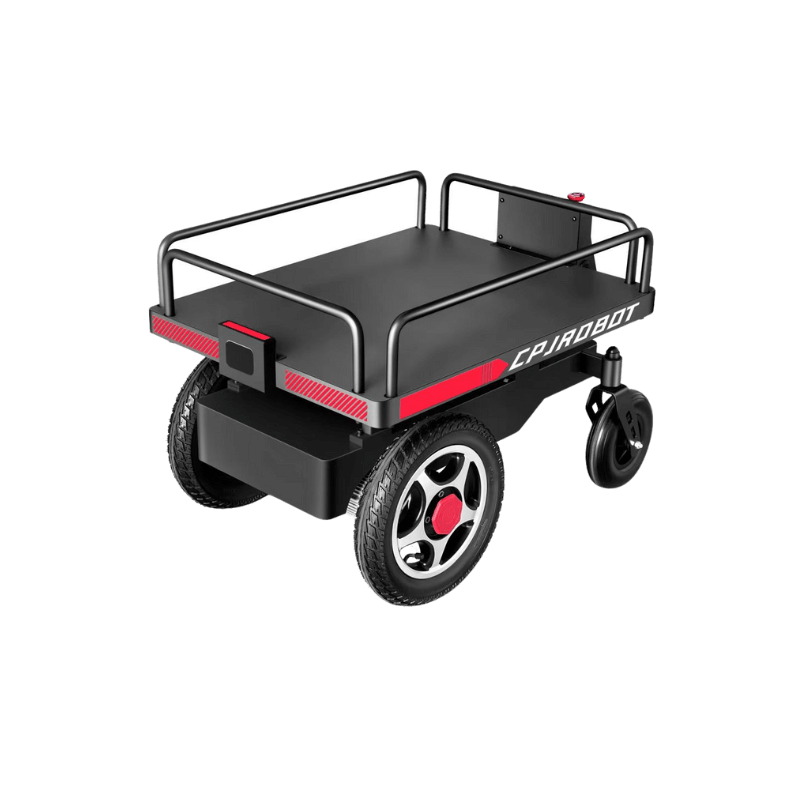

- Compact Design: Lightweight AGVs are typically smaller than traditional AGVs, making them ideal for navigating narrow aisles and tight corners in manufacturing and warehouse environments.

- High Maneuverability: Equipped with advanced navigation systems such as LiDAR or vision-based technologies, lightweight AGVs can operate with precision, avoiding obstacles and dynamically adjusting their paths as needed.

- Energy Efficiency: These AGVs consume less energy than larger units, making them a more sustainable option for continuous operation.

- Scalability: Lightweight AGVs are often modular, allowing businesses to scale their material handling systems as operational needs grow.

- Customizability: CPJ ROBOT offers customizable solutions, allowing businesses to adapt AGV features—such as speed, payload capacity, and navigation systems—based on specific requirements.

2. Advantages of Lightweight AGVs in Manufacturing and Warehousing

The deployment of lightweight AGVs brings a host of benefits to both manufacturing and warehousing operations. These advantages not only optimize material handling but also contribute to a smarter, more efficient workflow.

- Improved Efficiency: Lightweight AGVs are faster and more precise than human-operated forklifts or carts, drastically reducing the time it takes to transport materials from one point to another. This leads to improved throughput and faster order fulfillment.

- Reduced Labor Costs: As AGVs take over repetitive material handling tasks, companies can reduce reliance on manual labor. This allows workers to focus on more complex tasks, ultimately leading to a more skilled workforce while reducing labor costs.

- Enhanced Safety: AGVs come equipped with built-in safety features, including sensors that detect obstacles and prevent collisions. This significantly reduces the risk of workplace accidents, particularly in environments with high traffic or heavy machinery.

- Workflow Optimization: Lightweight AGVs can be integrated with warehouse management systems (WMS) and manufacturing execution systems (MES), automating the flow of materials throughout the facility. This creates a seamless workflow, reducing bottlenecks and improving overall productivity.

- Flexibility in Task Handling: From transporting raw materials to delivering finished goods, lightweight AGVs can handle a wide range of tasks within the facility. Their adaptability makes them an essential component of flexible manufacturing systems.

3. Industries Where Lightweight AGVs Are Becoming Essential

As businesses increasingly turn to automation to stay competitive, lightweight AGVs are becoming a critical tool across multiple industries. Some sectors where these vehicles are particularly transformative include:

- Manufacturing: In automotive, electronics, and consumer goods manufacturing, lightweight AGVs are used to transport components, tools, and products between different stages of production. Their ability to seamlessly integrate with automated assembly lines boosts production efficiency.

- Warehousing and Distribution: E-commerce giants and logistics companies are adopting lightweight AGVs to streamline their warehousing operations. These AGVs can pick, sort, and transport items within fulfillment centers, significantly speeding up the order processing time.

- Healthcare: Hospitals and medical centers are deploying lightweight AGVs to deliver medications, supplies, and meals to different departments, allowing healthcare workers to focus on patient care.

- Food and Beverage: In food processing plants, lightweight AGVs handle raw materials and finished products, improving hygiene by reducing human contact with food items.

- Retail: Retail chains are beginning to implement AGVs in their warehouses and stores to manage inventory and restock shelves efficiently, ensuring that goods are always available for customers.

4. Customization Options for Lightweight AGVs by CPJ ROBOT

To meet the unique demands of different industries, CPJ ROBOT offers fully customizable lightweight AGV solutions. Businesses can choose from a range of customization options, including:

- Payload Capacity: Whether you need an AGV for light or heavy loads, CPJ ROBOT’s AGVs can be tailored to carry the right payload for your operation.

- Navigation Systems: CPJ ROBOT integrates advanced navigation technologies such as LiDAR and SLAM to ensure precise and autonomous movement, even in complex environments.

- Speed and Power Efficiency: Customize the speed and power consumption of your AGVs to align with your operational requirements, ensuring maximum energy efficiency and productivity.

5. The Future of Material Handling with Lightweight AGVs

The adoption of lightweight AGVs is set to increase as more businesses recognize the potential of automation in streamlining operations. In the future, we can expect to see more sophisticated AGVs with enhanced AI capabilities, enabling them to learn and adapt to changing environments in real-time.

As industries continue to evolve, so will the need for flexible, customizable material handling solutions. CPJ ROBOT remains at the forefront of this innovation, providing state-of-the-art lightweight AGVs that are designed to meet the specific needs of modern businesses.

Conclusion

Lightweight AGVs are transforming the landscape of material handling in manufacturing, warehousing, healthcare, and more. With their compact design, scalability, and ability to optimize workflows, these AGVs represent the future of efficient operations. CPJ ROBOT’s expertise in developing customizable lightweight AGVs ensures that businesses can find the perfect solution to improve efficiency, reduce costs, and stay competitive in a rapidly changing world.