In the fast-paced world of modern manufacturing, efficiency, safety, and worker comfort are paramount. As factories strive to remain competitive, automation plays a vital role. One particularly innovative solution that is gaining traction is the use of follow robots in factories. These robots are transforming the way materials are handled, tasks are completed, and safety protocols are enforced. But what exactly are follow robots, and how can they revolutionize factory operations? Let’s dive into their key applications, advantages, and why they are a game-changer for industries worldwide.

What are Following Robots?

Follow robots are autonomous machines designed to follow human workers or other robots while performing specific tasks. Often equipped with advanced technologies like LiDAR, cameras, and sensors, they can navigate complex environments and interact seamlessly with their surroundings. These robots are particularly well-suited for environments like factories, warehouses, and production lines where repetitive tasks or material transport require high efficiency and safety.

Key Applications of Following Robots in Factories

1. Material Handling and Transport

One of the most prominent applications of follow robots is in material handling. In large factories, workers are often tasked with moving heavy or bulky materials from one point to another. Follow robots can automate this process by trailing behind workers or other automated vehicles (AGVs) to deliver materials exactly where they are needed. This reduces the amount of manual labor, minimizes human error, and ensures the efficient flow of materials.

How It Works:

- Follow robots use real-time positioning and obstacle-avoidance systems to safely navigate the factory floor.

- They can track and follow the path of a worker or device, automatically delivering components or tools.

- Sensors and cameras ensure that robots can avoid obstacles, adapting to the ever-changing layout of the factory.

By automating material transport, factories can streamline operations and significantly reduce downtime.

2. Production Line Assistance

The assembly line is the heart of many manufacturing processes. Follow robots can assist in these environments by working alongside human workers, aiding them in various tasks like carrying tools, delivering materials, or even performing quality checks.

Key Benefits:

- Collaboration: These robots don’t just replace human workers; they complement them. They can follow workers through the production line, providing the necessary tools or parts to facilitate smoother and faster assembly.

- Efficiency: Automating routine tasks such as tool delivery means workers can focus more on higher-value tasks, enhancing overall productivity.

Additionally, follow robots equipped with vision sensors can inspect products for defects, improving the quality assurance process and reducing the chance of faulty products reaching customers.

3. Safety Inspections

Safety is always a priority in industrial settings, and follow robots are playing a crucial role in safety monitoring. These robots are equipped with sensors that allow them to patrol factory floors, monitor equipment status, and identify potential hazards in real-time. By automating safety inspections, factories can enhance their safety measures and reduce the likelihood of accidents.

How They Contribute to Safety:

- Real-time Monitoring: Follow robots equipped with sensors can detect environmental risks such as gas leaks, heat anomalies, or faulty equipment. This allows for immediate action before a minor issue becomes a major problem.

- Emergency Response: In case of an emergency, these robots can quickly reach the affected area, providing real-time data and assisting human workers in taking swift action.

With 24/7 monitoring, follow robots help ensure that factories are operating at optimal safety levels.

4. Warehouse Management

Managing inventories and ensuring that the right parts are available when needed is essential for smooth factory operations. Follow robots can assist with warehouse management by tracking materials, updating inventory, and even assisting with automated sorting and packaging.

What They Do:

- Inventory Tracking: Follow robots can be programmed to follow specific paths through the warehouse, scanning and updating inventory as they go. This helps ensure real-time tracking of materials and reduces errors in stock management.

- Automated Sorting: When integrated with sorting systems, follow robots can assist in categorizing and packaging materials, improving the speed and accuracy of these processes.

By streamlining warehouse operations, follow robots help ensure that production lines are never delayed due to material shortages or mismanagement.

Advantages of Follow Robots in Manufacturing

1. Increased Efficiency

Follow robots significantly improve factory efficiency by automating tedious and repetitive tasks. With the ability to move materials, deliver tools, and monitor equipment autonomously, these robots free up human workers to focus on more complex or creative tasks. This results in a more efficient workforce, reduced lead times, and fewer delays in production.

2. Enhanced Safety

Safety is often one of the biggest concerns in industrial environments, especially with heavy machinery and hazardous conditions. Follow robots can help prevent accidents by providing constant surveillance and quick emergency responses. Moreover, they can help eliminate the need for workers to perform dangerous or strenuous tasks, such as manually lifting heavy materials or walking long distances across the factory floor.

3. Improved Work Environment

Follow robots also enhance the working environment by reducing the physical strain on workers. By taking over heavy lifting and transporting materials, these robots help minimize the risk of injury and fatigue. Workers can now focus on tasks that require more cognitive input, improving overall job satisfaction and well-being.

4. Cost Savings

Over time, the use of follow robots can result in significant cost savings for manufacturers. By automating labor-intensive tasks and reducing the risk of accidents, companies can reduce operational costs. Additionally, the increased efficiency and productivity of workers directly translate into lower production costs.

Conclusion: The Future of Manufacturing with Follow Robots

Follow robots are no longer a futuristic concept; they are a reality in many factories today. From material handling and production line assistance to safety inspections and warehouse management, these robots are proving to be indispensable tools for modern manufacturing. By improving efficiency, safety, and the overall work environment, follow robots help companies meet the demands of a rapidly evolving industry.

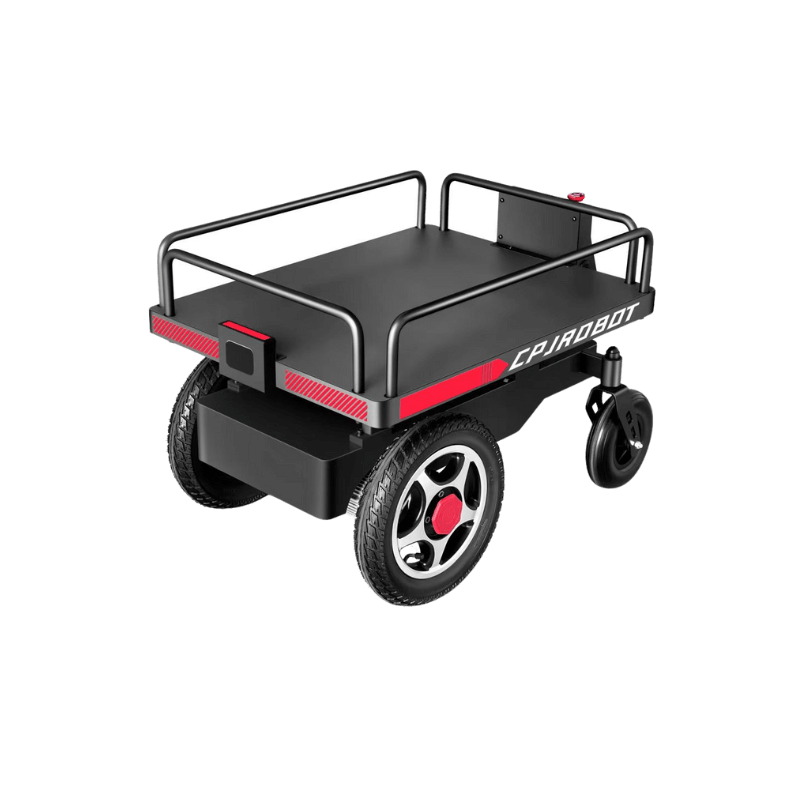

If you’re ready to explore how automation can elevate your factory operations, CPJ ROBOT is here to help. Specializing in LiDAR and intelligent robot manufacturing, CPJ ROBOT provides customized solutions designed to meet your unique operational needs. Reach out today to discover how follow robots and other innovative technologies can revolutionize your production processes.

Ready to take your factory automation to the next level? Contact CPJ ROBOT for expert guidance and cutting-edge solutions tailored to your needs. Let’s work together to build a safer, more efficient, and smarter factory.