Introduction

In today’s fast-paced industries, automation is key to maintaining efficiency and productivity. Autonomous robot chassis and lightweight Automated Guided Vehicles (AGVs) are foundational technologies that drive material handling, transportation, and service robot applications. However, the needs of different industries vary greatly, which is why companies like CPJ ROBOT specialize in offering customizable solutions for both autonomous robot chassis and lightweight AGVs.

This blog explores how customization options, such as payload capacities, navigation systems, and user interfaces, allow businesses to optimize their robotics solutions for specific applications.

1. The Importance of Customization in Robotics

Every industry has its unique set of operational requirements. For instance, warehouses prioritize high-speed, lightweight AGVs for quick order fulfillment, while industrial manufacturing environments may need rugged, heavy-duty chassis to transport large loads. The ability to customize both autonomous robot chassis and lightweight AGVs provides flexibility, allowing companies to tailor their automation systems to fit their operational demands.

CPJ ROBOT, specializing in the manufacturing of reception service robots, understands these industry-specific needs and offers customizable robotic solutions to enhance efficiency and performance in various sectors.

2. Customizing Autonomous Robot Chassis

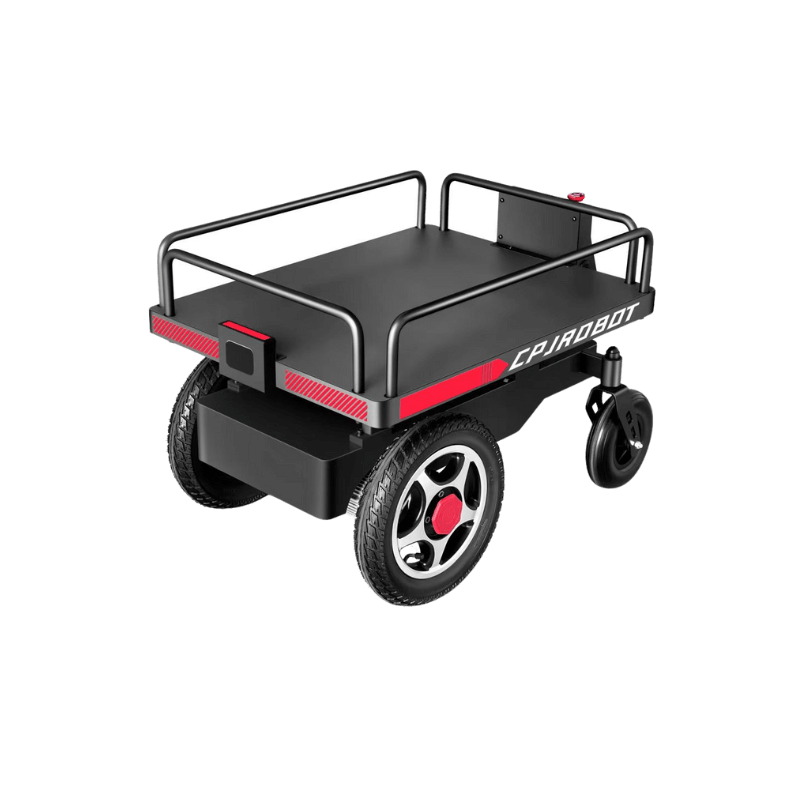

An autonomous robot chassis forms the foundation of many robotic systems. It defines the mobility, stability, and adaptability of robots in different environments. Customization options for robot chassis allow businesses to create solutions that precisely meet their operational goals. Here are some of the key aspects of customization:

- Payload Capacity:

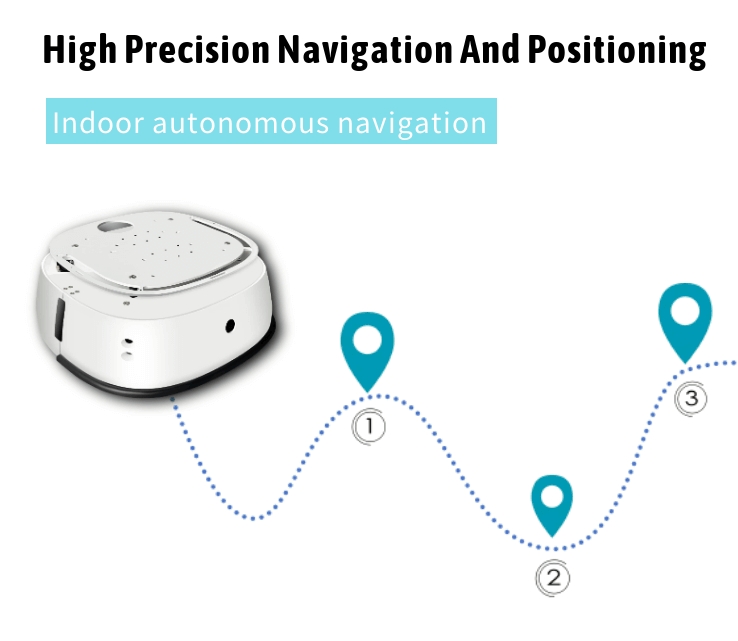

One of the most crucial customization aspects is the chassis’s payload capacity. Industries such as manufacturing or logistics require heavy-duty chassis that can carry significant loads, while environments like healthcare or hospitality might need lighter, more agile chassis to transport smaller items. CPJ ROBOT provides chassis options that can handle a wide range of payloads, making them suitable for different types of service robots. - Navigation Systems:

The environment in which the chassis operates determines the type of navigation system required. For indoor environments, LiDAR-based navigation provides precise positioning and obstacle detection, whereas outdoor environments might require GPS-based systems for broader movement. CPJ ROBOT offers advanced navigation technologies, including SLAM (Simultaneous Localization and Mapping), enabling robots to autonomously navigate through dynamic and unpredictable environments. - Terrain Adaptability:

The ability of a robot chassis to handle different terrains is crucial in certain industries. For instance, autonomous robots used in agriculture or construction sites must navigate uneven surfaces, while indoor robots typically operate on smooth floors. CPJ ROBOT provides chassis that can be adapted to various terrain requirements, ensuring optimal mobility across diverse environments. - Interfaces and Control Systems:

For businesses that require integration with existing systems, CPJ ROBOT offers open interfaces, allowing for easy customization and integration with other control systems. This flexibility supports advanced customization, making it easier for companies to manage and control the robot chassis through their current systems.

3. Customizing Lightweight AGVs for Specific Applications

Lightweight AGVs are becoming essential in industries such as warehousing, e-commerce, and healthcare, where quick, efficient, and precise material handling is required. Customization ensures these AGVs are optimized for the specific workflows of each industry.

- Payload Flexibility:

Like robot chassis, the payload capacity of AGVs can be customized based on the application. CPJ ROBOT offers lightweight AGVs that are capable of handling various load sizes, making them ideal for tasks ranging from transporting medical supplies in hospitals to moving inventory in warehouses. - Navigation and Safety Systems:

AGVs need to navigate autonomously in dynamic environments. LiDAR-based navigation is a common choice for lightweight AGVs as it provides accurate positioning and obstacle detection. Additionally, CPJ ROBOT’s AGVs come with safety systems such as collision avoidance sensors and automatic braking, which are essential for safe operations in environments where humans and machines coexist. - Custom Workflows and Task Handling:

AGVs can be customized to perform a wide range of tasks depending on the needs of the industry. Whether it’s transporting raw materials in a manufacturing plant or delivering items to different hospital departments, CPJ ROBOT’s AGVs are tailored to match specific workflows. Companies can choose from a variety of task modules, including picking, sorting, and autonomous delivery functions. - Software and Interface Integration:

To ensure seamless integration into a company’s existing operations, lightweight AGVs need to be compatible with warehouse management systems (WMS), enterprise resource planning (ERP) systems, and other software platforms. CPJ ROBOT provides AGVs with customizable software interfaces, making it easier for businesses to manage and monitor AGV tasks through their current systems.

4. Industries Benefiting from Customized Robot Chassis and AGVs

The ability to customize robotic solutions makes autonomous robot chassis and lightweight AGVs adaptable across a wide range of industries. Here are a few examples:

- Manufacturing:

In manufacturing plants, where material handling and production efficiency are critical, customizable AGVs and robot chassis are used to transport heavy loads and streamline production processes. CPJ ROBOT provides solutions that enhance flexibility in automated material handling. - Healthcare:

In hospitals and clinics, lightweight AGVs equipped with navigation and delivery systems are being used to transport medical supplies, documents, and equipment between departments, freeing up healthcare workers to focus on patient care. Customization options allow hospitals to design AGVs for specific medical workflows. - Warehousing and Logistics:

Warehouses are increasingly relying on lightweight AGVs to automate picking, sorting, and transporting tasks. With customizable payloads and navigation systems, CPJ ROBOT’s AGVs are helping warehouses optimize workflow and improve order fulfillment efficiency. - Retail:

Customizable AGVs in retail environments are used for restocking shelves, transporting products, and managing inventory. These AGVs are tailored to fit the specific needs of the retail space, ensuring smooth and efficient operation.

5. The Future of Customizable Robotic Solutions

As industries continue to adopt automation, the demand for customizable robotic solutions will only grow. Businesses will require more tailored, flexible options that can be integrated into their unique operations. With companies like CPJ ROBOT, which specialize in providing customizable autonomous robot chassis and lightweight AGVs, businesses can ensure that their robotic systems are optimized for maximum efficiency, flexibility, and adaptability.

Whether it’s in manufacturing, healthcare, warehousing, or any other industry, CPJ ROBOT’s customizable solutions provide businesses with the tools they need to stay competitive and future-proof their operations.

Conclusion

Customization is key when it comes to autonomous robot chassis and lightweight AGVs. The ability to tailor these systems to meet specific operational requirements allows businesses to improve efficiency, reduce costs, and streamline workflows. CPJ ROBOT is at the forefront of this revolution, offering fully customizable solutions that meet the diverse needs of modern industries.