In the fast-evolving world of warehouse logistics, businesses are constantly seeking ways to improve efficiency, reduce costs, and enhance safety. Traditional material handling tools like forklifts and hand carts have long been the backbone of warehouse operations. However, with the rise of automation, TrackBot, an intelligent logistics robot, is emerging as a game-changer. But how does TrackBot compare to traditional tools like forklifts and hand carts? In this blog, we’ll explore the pros and cons of both options, focusing on automation, flexibility, ease of operation, and adaptability to different environments. By the end, you’ll understand why TrackBot is the future of smart logistics.

Traditional Material Handling Tools: Pros and Cons

1. Forklifts

Forklifts are a staple in warehouses for lifting and transporting heavy loads. However, they come with limitations:

- Pros:

- High load capacity (up to several tons).

- Suitable for stacking and retrieving pallets in high racks.

- Cons:

- Requires skilled operators, increasing labor costs.

- Limited maneuverability in narrow or crowded spaces.

- High risk of accidents due to human error.

- High maintenance and fuel/electricity costs.

2. Hand Carts

Hand carts are simple, manual tools used for moving smaller loads.

- Pros:

- Low cost and easy to use.

- No need for specialized training.

- Cons:

- Limited load capacity and efficiency.

- Reliant on manual labor, leading to fatigue and slower operations.

- Not suitable for heavy or bulky items.

While traditional tools have their place, they often fall short in meeting the demands of modern warehouse logistics, which require higher efficiency, flexibility, and automation.

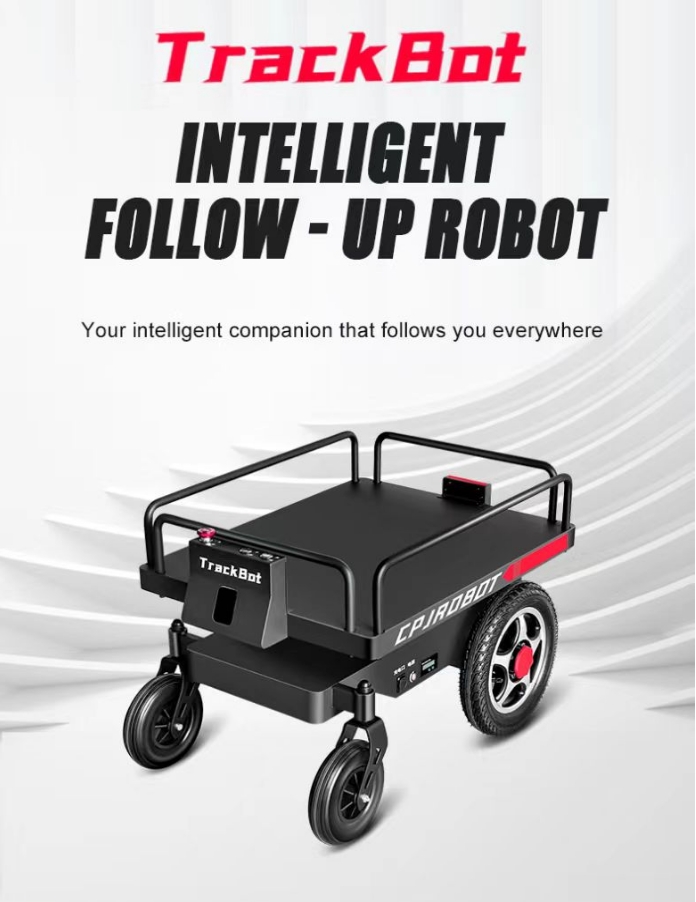

TrackBot: The Future of Smart Logistics

TrackBot is an intelligent logistics robot designed to address the limitations of traditional tools. Here’s how it compares:

1. Automation

- TrackBot: Equipped with advanced auto-follow technology, TrackBot can autonomously follow workers or navigate predefined paths. This reduces the need for manual intervention and significantly boosts efficiency.

- Traditional Tools: Forklifts and hand carts require constant human operation, leading to higher labor costs and slower workflows.

2. Flexibility

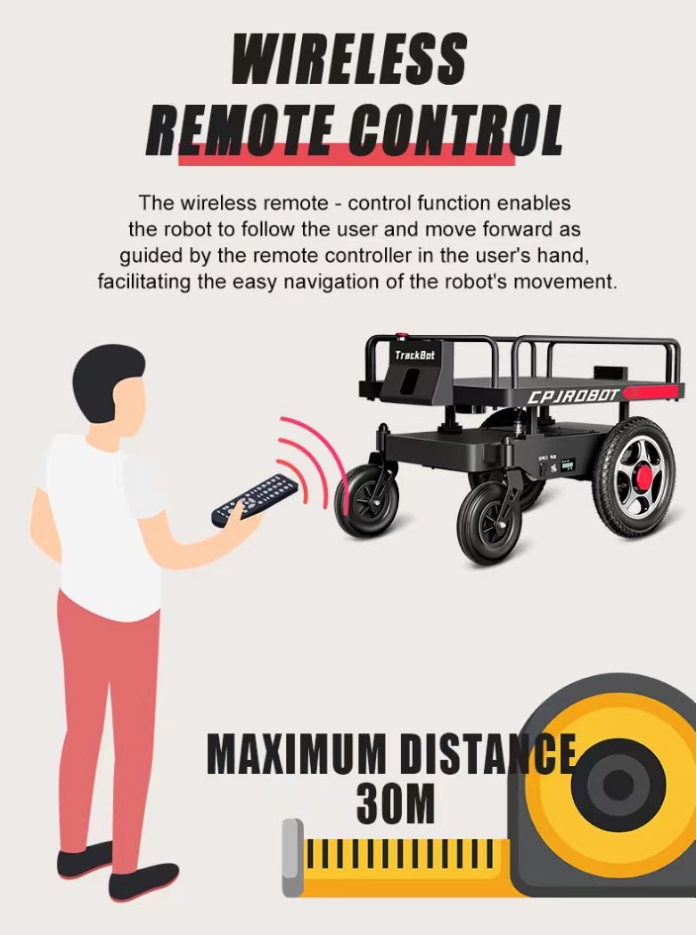

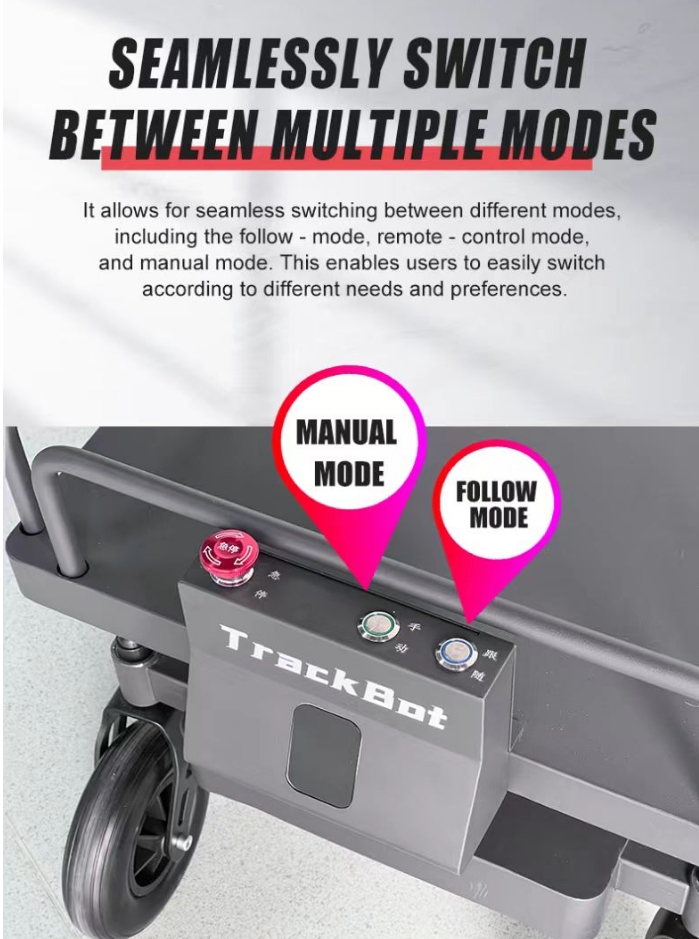

- TrackBot: With its compact design and intelligent obstacle avoidance, TrackBot can easily navigate narrow aisles and crowded spaces. It also offers multi-mode switching, allowing users to switch between auto-follow, remote control, and manual modes.

- Traditional Tools: Forklifts are bulky and difficult to maneuver in tight spaces, while hand carts lack the versatility to handle complex tasks.

3. Ease of Operation

- TrackBot: TrackBot’s wireless remote control and intuitive interface make it easy to operate, even for non-technical users. Its autonomous features reduce the need for specialized training.

- Traditional Tools: Forklifts require certified operators, and hand carts, while simple, rely heavily on manual effort.

4. Adaptability to Different Environments

- TrackBot: Designed for both indoor and outdoor use, TrackBot can seamlessly transition between environments like warehouses, factories, and agricultural settings. Its advanced sensors ensure stable performance on uneven terrain or in low-light conditions.

- Traditional Tools: Forklifts are primarily designed for indoor use, while hand carts are limited by their manual operation and lack of adaptability.

5. Safety

- TrackBot: With intelligent obstacle avoidance and real-time sensor data, TrackBot minimizes the risk of collisions and accidents. It also features an auto-stop function if it exceeds the set safety distance.

- Traditional Tools: Forklifts pose a higher risk of accidents due to human error, and hand carts offer no safety features.

Key Advantages of TrackBot in Modern Warehouse Logistics

- Increased Efficiency: TrackBot automates repetitive tasks, allowing workers to focus on higher-value activities.

- Cost Savings: By reducing reliance on manual labor and minimizing errors, TrackBot helps lower operational costs.

- Enhanced Safety: Its autonomous features reduce the risk of workplace injuries and accidents.

- Versatility: TrackBot’s ability to operate in diverse environments makes it suitable for a wide range of applications.

Real-World Applications of TrackBot

– Warehouse Operations

TrackBot can transport goods across large warehouses, reducing the need for manual carts or forklifts. Its auto-follow feature ensures it keeps up with workers, while its intelligent obstacle avoidance prevents collisions.

– Factory Floors

In manufacturing plants, TrackBot delivers tools and components to different stations, streamlining production processes and reducing downtime.

– Agricultural Settings

TrackBot is also making waves in agriculture, where it transports produce within greenhouses or across fields. Its ability to navigate uneven terrain and avoid obstacles makes it a valuable asset.

– Retail Environments

In large supermarkets, TrackBot assists with restocking shelves and transporting goods, ensuring efficient operations.

Conclusion: Why TrackBot is the Better Choice

While traditional material handling tools like forklifts and hand carts have their uses, they often fall short in meeting the demands of modern warehouse logistics. TrackBot, with its advanced auto-follow technology, intelligent obstacle avoidance, and wireless remote control, offers a smarter, safer, and more efficient solution.

By automating repetitive tasks, reducing labor costs, and enhancing safety, TrackBot is transforming the way businesses approach material handling. Whether you’re managing a warehouse, operating a factory, or working in agriculture, TrackBot is the ultimate tool for modern smart logistics.

Embrace the future of warehouse logistics with TrackBot and experience the transformative power of intelligent automation.

Keywords: TrackBot, smart logistics, warehouse robotics, auto-follow technology, intelligent obstacle avoidance, warehouse efficiency, material handling automation, modern warehouse solutions.